Lithography comes from an Ancient Greek word ‘lithos’ which means stone ‘graphein’ which means to write. The printing is done using a metal plate or hard lithographic limestone. The method uses the solution of oil and water. Invented by a German author and actor, Alois Senefelder, in 1976, it is primarily considered as a cheaper way of printing theatrical masterpieces.

Utilizing the system that oil and water don’t mix, Senefelder realized that the lithography printmaking process while trying to find ways of making multiple copies of his song and plays for theater-used. Senefelder favorably engaged the process of reversed printing by trying the fluids made of liquid wax, rainwater, and soap combined into a limestone.

The process of lithography printmaking starts by drawing an image with oil on a smooth and level lithographic limestone surface. Others use fat or wax. Then, a mixture of acid is etched on the parts of the stones which are not preserved by the grease-based image.

Once the stone moistened, the etched areas preserved water. Only then will the oil-based ink be applied, and this would be repelled by the water and get attached only to the primary drawing. Then the ink is transferred into a blank paper sheet where it will produce a printed page.

Modern Lithography

In modern times lithography printmaking is used to create posters, maps, newspapers, and even packaging. It is also used in about any smooth surface items with prints and graphics on them. Books are also done through lithography printmaking and undergo a printing process called offset lithography.

Instead of stone tablets like traditional lithography, offset lithography uses a photographic process, aluminum, polyester, and printing plates made of paper.

Though lithography printmaking was first invented by Senefelder, it wasn’t until years later that it was fully adopted. In 1918, it was widely used for the generation of a press that automatically moistened and inked the plate, producing it quicker and easier. It was in 1875 than offset press lithographic is invented, which makes it way easier and better.

Offset Lithography Process

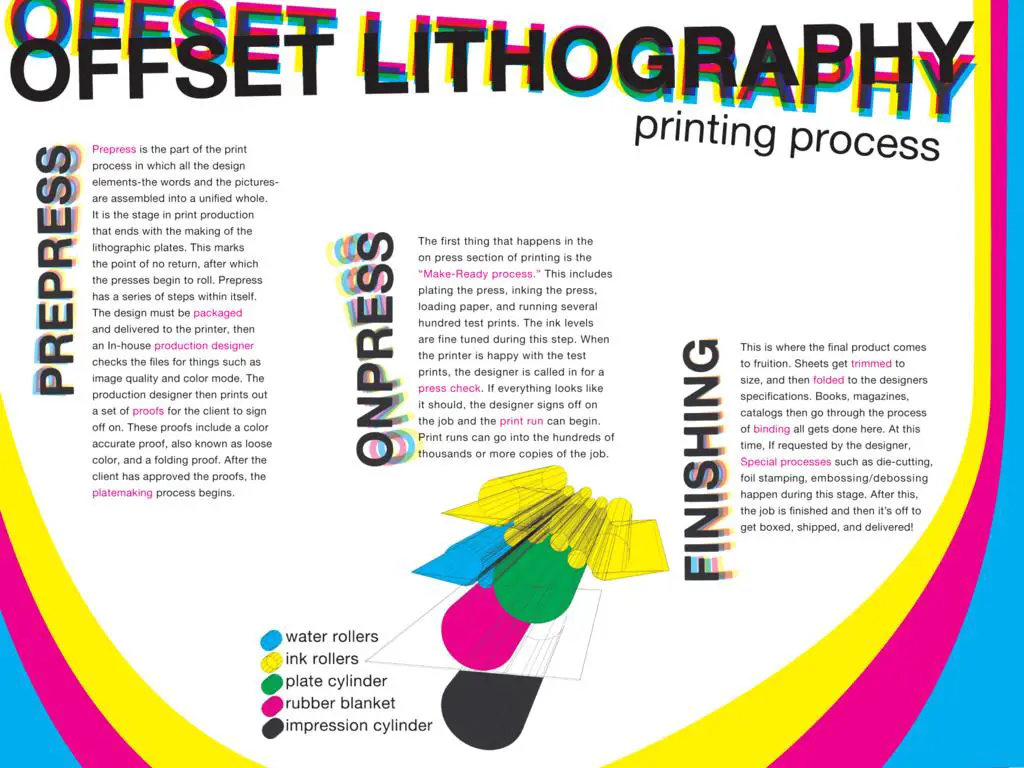

The offset lithography process is more than just modern computer printing an image. There is a need to know the entire process, properties, and structure to know what happens between the water, paper, and ink.

The design of the image and text is etched and transferred using the laser into various layers of aluminum called the press late. Each press plate is positioned into a cylinder in every printing unit. Color printing usually follows the color model CYMK or the colors cyan, magenta, yellow, and black.

The process starts with the press plate rotating around the machine and gets its first contact in the dampening unit where a blend of chemicals and water moistens the non-image sections of the press plate.

The press plate continues to move and will reach the inking unit. From the ink fountain, the ink will move through a roller train or various rollers. These rollers or the roller train takes ink into the image areas or sections of the press plate.

Then it will gradually move into the blanket cylinder where the paper plate is dried out of the water, and the inked image section is picked up. The last cylinder is called the impression cylinder. The image is pressed between the blanket and the impression cylinder—the transfer drum, which has grippers transfer the paper from the previous cylinder to the next one. The paper passes through each unit, and once done, the hot and cool air will dry them out. Lastly, it will be placed in a room ready for delivery.

Notable Innovations

Over time, many innovations and technical modifications are done in the printing process. One of them includes the development of presses, a mechanical device used to apply pressure to the inked surface, which causes a secure and a firm transfer, with added units that can imprint multi-color images in one pass.

An added great innovation is the continuous dampening system founded first by Dahlgren. Instead of using the conventions way of moistening the plater just like the older presses do, rollers are now covered with molleton cloth, which quickly absorbs water. Because of the easy control of the water flow, there is a good balance between ink and water.

Lithography Printmaking Used Today

The offset process is the most popular method used today. The process is relatively easy, which only consists of an ink images printer on a rubber cylinder and then transferred on paper or other materials. Because of the rubber cylinders’ flexible attributes, offset lithography is also used to print on cloth, leather, tin, wood, and other smooth or even rough surfaces.

Offset printing years ago is mostly used to make calendars, books, magazines, maps, stamps, labels, packaging, or other advertising matters. All are printed in large numbers. The 21st century became an outlet for a large number of artists to use the offset process to make non-commercial ends. Now, offset lithography printmaking produces high quality and detailed prints at a faster speed. The process is faster, and the quality is better.

Conclusion

Lithography printmaking has come a long way. From a simple yet tedious way of traditional lithography to easier and faster innovations today, lithography’s changes and development mirrors how technology can make the process easier.

Now, modern lithography printmaking is one of the must-haves for commercial and printmaking. Without offset printmaking, there wouldn’t be labels, newspapers, books, and other commercial things people need. Indeed, lithography printmaking has been widely used today to create most of the things people are already familiar with. It is always when great problems arise, do people and technology find ways to keep life easier and better.