If you are planning to start your very own lapidary project, whether for passion or for a living, one thing that you need to have is a lapidary saw. This type of saw is designed specifically to cut gemstones or rocks into shapes or slices that are used for creating jewelry pieces. The rocks that are then cut can be turned into either faceted stones or cabochons. They may also be utilized in cutting geodes.

After securing the lapidary rough pieces, your work has just started when it comes to cutting beautiful and high quality stone slabs that can be used for cabbing. The process of cutting some rough and turning them into slabs can turn out to be time-consuming, most particularly when using slow cutting and self-feed diamond saws that come with oil lubricants.

Diamond saws are often a huge investment, as there are models that reach over $1500. While they are expensive, they may be the best tools that you can get, especially the ones that are oil lubricated, as if they are used especially in cutting specimens, displaying slabs, as well as large rough since the surface of the slab is smoother and ready for polishing.

On the other hand, for cabbing slabs, diamond saws are generally too expensive and even time consuming since there is a need to perform cutting at a slow speed, along with removing the surface oil out of the slabs right before cabbing.

The Right Way of Using a Lapidary Saw

When it comes to using a lapidary saw, there are some techniques and tips that you can keep in mind:

· The Right Positioning

In using a lapidary saw, you can start by lining up your rough or slab against the tool’s rip fence. Another option is using the saw vise attachment. You may also just firmly hold the rock alternatively using both hands, with one hand on every side of the blade. Ensure that the blade of the saw is fed continually with either oil or water while guiding your piece in manually.

· Start Slowly

When operating a saw, it is vital to go in slowly, allowing the blade to perform the job for you. In this way, you can expect to create a smooth and clean cut each time while also avoiding any potential chips and unwanted accidents.

· Hand Cutting Tips

If you want to further improve your productivity while reducing on some cost, you may want to begin hand cutting rough. This can be done with the use of a water-cooled tile saw. Generally, the process becomes 10 times faster since the cutting speed of this type of saw is relatively faster. At the same time, it also removes all of the other steps mentioned above, including removing oil out of the slabs.

· Water Cooled Tile Saw

Hand cutting also enables you to easily see the rocks immediately on the cutting surface so that you can also flip it over if you notice that the pattern did not turn out the way you want to be. At the same time, it is also possible to cut a piece of rough with a 5 inch diameter into 5 slabs in a very short period of time, even less than 15 minutes. Lastly, since the tile saw is water-cooled, there is no need to handle oil, which means that that it is generally better for the environment.

Slabs that are hand-cut may not be dimensionally perfect, but they are presentable enough for cabs. A disadvantage, however, is that the blade of this saw wears faster than other types. However, the investment that you need for using a tile saw is relatively less. In order to make a tile saw effective for use indoors, you can place a removable altered storage box made of plastic over the frame in order to ensure the presence of water mist.

· Using a Splash Shield

You can also opt to place a splash shield, along with light towards the end. Another option that you can do is hooking up a water feed tube, as well as a drain. You may also begin using a fast and affordable slab cutting. Manually cutting slabs may look dangerous, but by simply ensuring safety by wearing a face mask in order to avoid unnecessarily breathing in silica that is brought by the water mist.

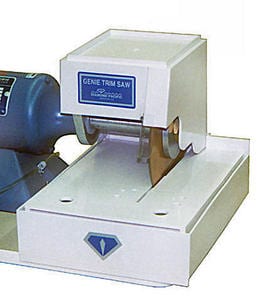

Other Types of Lapidary Saws

Aside from hand saws, there are also two other types of saws that are often used in lapidary – slab saws and trim saws. Generally, slab saws have thicker and larger blades compared with trim saws. As such, slab saws are recommended for cutting bigger rough pieces of rock, creating 1/8” to ¼” of slabs that are used for making cabochon or cutting geodes.

On the other hand, saws are designed to have finer blades. This will allow this type of saw to cut into the slabs similar to that of a pre-drawn cabochon shape in an amazing level of accuracy. As a bonus, it leaves a minimum or little waste.

Conclusion

The type of saw that you will use for your lapidary project highly depends on your preferences, and your skills. If you are considering lapidary as a serious hobby, you may want to get the right tools to do the job. You may start with the basic ones, eventually adding more as you learn more of the craft.